Dimensions

What is Dimensional Calibration?

In mechanical calibration, the process of verifying and modifying the precision of devices used to measure physical dimensions including length, width, thickness, and angles is known as “dimensional calibration.” It guarantees that measurement instruments give accurate and trustworthy readings in compliance with national or international standards.

Common Dimensional Instruments and Equipment

1.Vernier Micrometer

A Vernier Micrometer is a type of precision measuring device that is used to measure small dimensions with a very high degree of accuracy. These measurements are usually in the micrometer (µm) range. It provides measurements up to 0.001 mm (1 micron) by combining the concepts of a vernier scale with a micrometer screw gauge.

2.Sleeve Gadget Set

A Sleeve Gadget Set in mechanical calibration refers to a set of precision cylindrical blocks or sleeves, typically made of hardened steel or carbide, used to calibrate and verify the accuracy of external micrometers. Each sleeve has a specific, certified length and is used as a reference standard.

3.lever Dial Gauge

In mechanical calibration, a lever Dial Gauge, sometimes referred to as a test indication, is a precision measurement tool used to identify small modifications to surface alignment, flatness, or roundness. Its pivoting lever arm rotates a dial needle, enabling extremely fine displacement measurements, usually in the micron range.

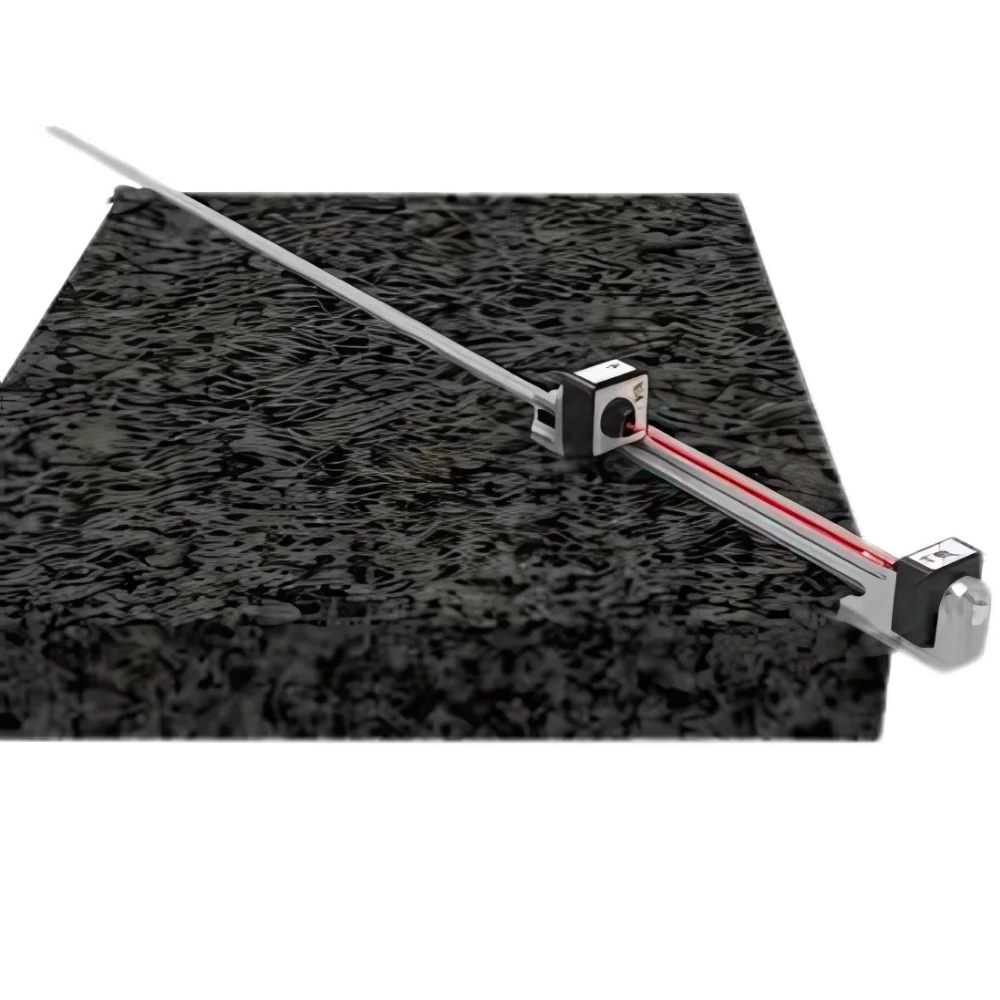

4.Surface Plates

Surface Plates are hardy, leveled reference bases composed of cast iron or granite that are used to check and adjust the accuracy and flatness of parts. They guarantee excellent precision in calibration activities by offering a trustworthy surface for measurements, dimensional checks, and tool settings.

5.Comparator Stand

In mechanical calibration, a Comparator Stand serves as a sturdy foundation for holding lever gauges or dial indications in position. During calibration procedures, it enables accurate and reproducible measurements of small dimensional changes like thickness, height, or flatness.

Benefits of Dimensional Calibration

Dimensional calibration benefits include:

- Accuracy & Precision: Guarantees that measuring devices give accurate readings.

- Consistency: Preserves accurate measurements across equipment and throughout time.

- Regulation: Fulfills regulatory requirements or industry standards such as ISO or NABL.

- Better Quality Control: Assists in identifying errors early in the production process.

- Lowering Expenses: Lowers product recalls, waste, and rework.

- Monitoring: Creates a chain of standard measurements connected to national and international units.

- Instrument Life Expectancy: Equipment life can be maintained and increased with routine calibration.

Why Choose Kesar Testing Service LLP for Dimensional Calibration?

At Kesar Testing Service LLP, we provide precise dimensional calibration using a specific set of precision instruments. We have Lever Dial Gauges to detect minor linear displacements, Sleeve Gauge Sets to confirm micrometer accuracy, and Vernier Micrometers for accurate length and thickness measurements. Additionally, we use Comparator Stands to provide steady, repeatable measurements during gauge calibration and premium Surface Plates as reference bases for flatness testing. We guarantee that every dimensional measuring tool satisfies industrial requirements and produces consistently accurate results across applications with this thorough setup.